CAPABILITIES

From Prototype to Production

Our responsive team and nimble operations help you get from concept to market faster—with consistent quality and support at every step.

CAPABILITIES

From Prototype to Production

Our responsive team and nimble operations help you get from concept to market faster—with consistent quality and support at every step.

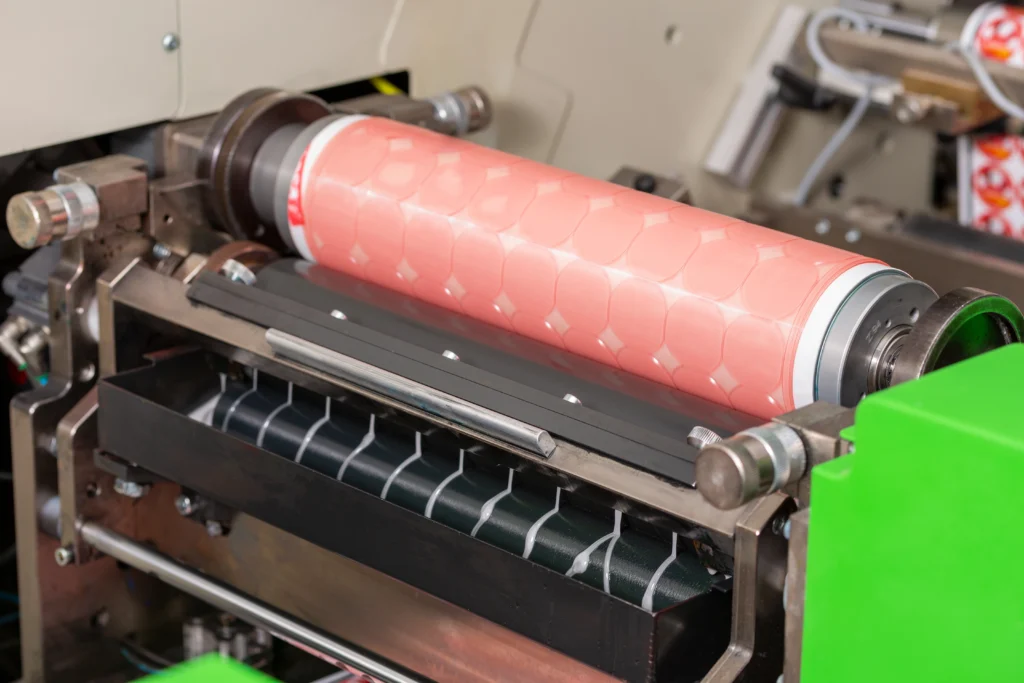

Precision Rotary Die Cutting